Introduction In this article we provide information about what is Construction work hsn code and Construction work hsn code and gst on construction work. 7D Plans launched an offer about getting your house plan free just contact us. What is construction work hsn code The Harmonized System of Nomenclature (HSN) code for construction work...<a href="https://impressivearchitecture.com/2023/12/15/construction-work-hsn-code-and-gst-on-construction-work/" class="epl-more-link">Read More→</a>

Category: MATERIALS

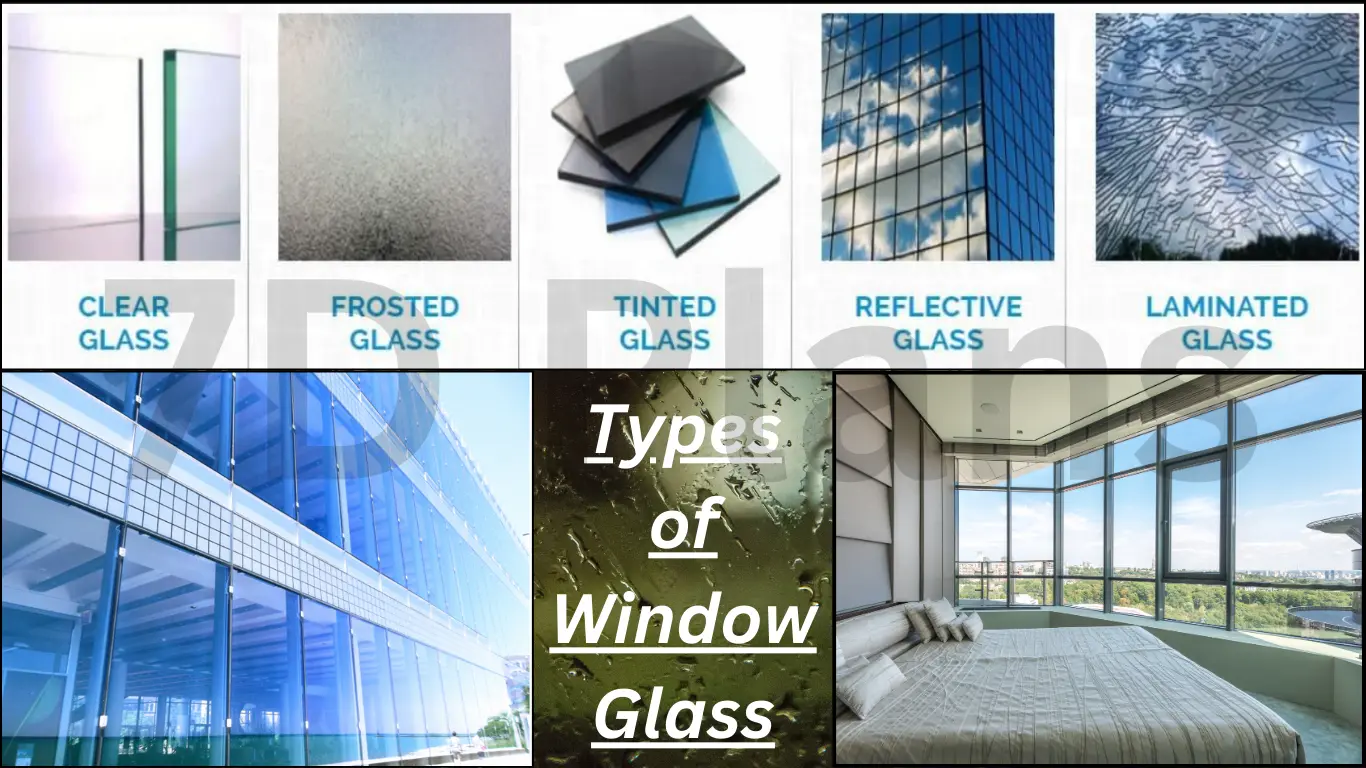

Types of Window Glass, Choices and Future Trends

Introduction Selecting the proper types of window glass is important for numerous motives. The right choice can affect energy efficiency, safety, privacy, and the overall comfort of a residing or running area. In this comprehensive exploration, we delve into the not unusual and specialized sorts of window glass, factors influencing picks, installation recommendations, case studies,...<a href="https://impressivearchitecture.com/2023/12/12/types-of-window-glass-choices-and-future-trends/" class="epl-more-link">Read More→</a>

A Guide for How to Design a House Like an Architect – 7D Plans

Introduction In this article we mentioned how to design a house like an architect and the architectural design manner from beginning to finish step by step. We recognize that each purchaser has special challenge goals, consisting of capability, perspectives, energy performance, or improving existing situations, and these goals ought to manual the design manner. For...<a href="https://impressivearchitecture.com/2023/12/11/a-guide-for-how-to-design-a-house-like-an-architect/" class="epl-more-link">Read More→</a>

#1 Best free 500 sq ft house plans -7D Plans

Introduction In the world of house plans, the choices can be overwhelming. This 7D Plans manual aims to simplify the procedure, focusing on the critical components of designing your dream home. We’ll delve into the intricacies of 500 sq ft house plans, emphasizing the importance of efficient layout for a comfortable and practical dwelling...<a href="https://impressivearchitecture.com/2023/11/23/1-best-free-500-sq-ft-house-plans-7d-plans/" class="epl-more-link">Read More→</a>

#1 Best free 800 sq ft house plans – 7D Plans

Introduction Overview of 800 sq ft House Plans The idea of 800 sq ft house plans has received massive recognition in recent years. These plans, often related to small houses, provide a completely unique blend of coziness and practicality. The awareness here isn’t always just on creating a shelter however on designing a space that...<a href="https://impressivearchitecture.com/2023/11/22/800-sq-ft-house-plans/" class="epl-more-link">Read More→</a>

#1 Best Free 900 square feet house plans 3d – 7D Plans

Introduction Discover the freedom of personalized living with our free 900 square feet house plans 3d. Elevate your design journey with 7D Plan Architect Company, where innovation meets imagination. Last 12 months we have laid out 1,700 house plans. 7D Plans have 10+ years experience in architecture and interior design fields. Importance of 3D House...<a href="https://impressivearchitecture.com/2023/11/15/900-square-feet-house-plans-3d/" class="epl-more-link">Read More→</a>

#1 Best Free 1000 sq ft house plans – 7D Plans

Introduction 1000 sq ft house plans stand as a testament to balance and thoughtful living spaces. At 7D Plans, our commitment to remodeling aspirations into Real systems is unwavering, and our series of the “Best Free 1000 sq ft House Plans” exemplifies this determination to excellence. We make thousands of house plans, 7D plans is...<a href="https://impressivearchitecture.com/2023/11/14/1000-sq-ft-house-plans/" class="epl-more-link">Read More→</a>

#1 Best Free 1200 sq ft house plans – 7D Plans

Introduction 1200 sq ft house plans complete guide, we will delve deep into every thing of creating the appropriate 1200 sq ft house plans. From expertise and its importance to navigating key issues, this guide will equip you with the know-how and notion you need to make your dream domestic a fact. we make thousand...<a href="https://impressivearchitecture.com/2023/11/12/1200-sq-ft-house-plans/" class="epl-more-link">Read More→</a>

New parliament building built by which company

Introduction The New Parliament Building in India, built through Tata Projects Limited, stands as a testament to the nation’s dedication to modernity, democratic governance, and architectural excellence. Nestled within the coronary heart of New Delhi, this architectural surprise seamlessly blends subculture with modern layout, containing the wealthy cultural background and democratic values that India upholds....<a href="https://impressivearchitecture.com/2023/11/10/new-parliament-building-built-by-which-company/" class="epl-more-link">Read More→</a>

Best East Facing House Elevation Double Floor Designs

Let’s showcase the charm and sophistication of East Facing House Elevation Double Floor design through the lens of 7D Plans, We are a main architectural firm recognized for its modern and visionary method. Last year we laid out 1,700 house plans. 7d plan is a budget pleasant architectural company with thousands of satisfied clients. Unveiling...<a href="https://impressivearchitecture.com/2023/11/09/east-facing-house-elevation-double-floor-2/" class="epl-more-link">Read More→</a>