Role of Horizontal Bands , DESIGN OF LINTLE BEAM , INDIAN STANDARD

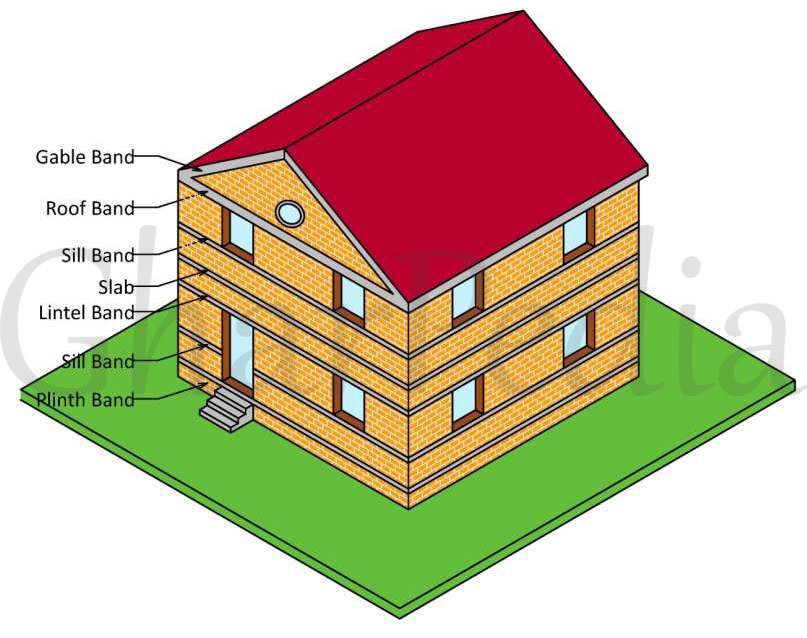

Role of Horizontal Bands :-

Horizontal bands are the most important earthquake-resistant feature in masonry buildings. The bands are provided to hold a masonry building as a single unit by tying all the walls together, and are similar to a closed belt provided around cardboard boxes. There are four types of bands in a typical masonry building, namely gable band, roof band, lintel band and plinth band , named after their location in the building. The lintel band is the most important of all, and needs to be provided in almost all buildings. The gable band is employed only in buildings with pitched or sloped roofs. In buildings with flat reinforced concrete or reinforced brick roofs, the roof band is not required, because the roof slab also plays the role of a band. However, in buildings with flat timber or CGI sheet roof, roof band needs to be provided. In buildings with pitched or sloped roof, the roof band is very important. Plinth bands are primarily used when there is concern about uneven settlement of foundation soil. The lintel band ties the walls together and creates a support for walls loaded along weak direction from walls loaded in strong direction. This band also reduces the unsupported height of the walls and thereby improves their stability in the weak direction. During the 1993 Latur earthquake (Central India), the intensity of shaking in Killari village was IX on MSK scale. Most masonry houses sustained partial or complete collapse . On the other hand, there was one masonry building in the village, which had a lintel band and it sustained the shaking very well with hardly any damage .

Design of Lintel Bands :-

During earthquake shaking, the lintel band undergoes bending and pulling actions . To resist these actions, the construction of lintel band requires special attention. Bands can be made of wood (including bamboo splits) or of reinforced concrete (RC) (Figure 4); the RC bands are the best. The straight lengths of the band must be properly connected at the wall corners. This will allow the band to support walls loaded in their weak direction by walls loaded in their strong direction. Small lengths of wood spacers (in wooden bands) or steel links (in RC bands) are used to make the straight lengths of wood runners or steel bars act together. In wooden bands, proper nailing of straight lengths with spacers is important. Likewise, in RC bands, adequate anchoring of steel links with steel bars is necessary.

Indian Standards:-

The Indian Standards IS:4326-1993 and IS:13828 (1993) provide sizes and details of the bands. When wooden bands are used, the cross-section of runners is to be at least 75mm×38mm and of spacers at least 50mm×30mm. When RC bands are used, the minimum thickness is 75mm, and at least two bars of 8mm diameter are required, tied across with steel links of at least 6mm diameter at a spacing of 150 mm centers.